"TheHondaBro" (wwaveform)

"TheHondaBro" (wwaveform)

03/11/2016 at 18:03 ē Filed to: None

1

1

37

37

"TheHondaBro" (wwaveform)

"TheHondaBro" (wwaveform)

03/11/2016 at 18:03 ē Filed to: None |  1 1

|  37 37 |

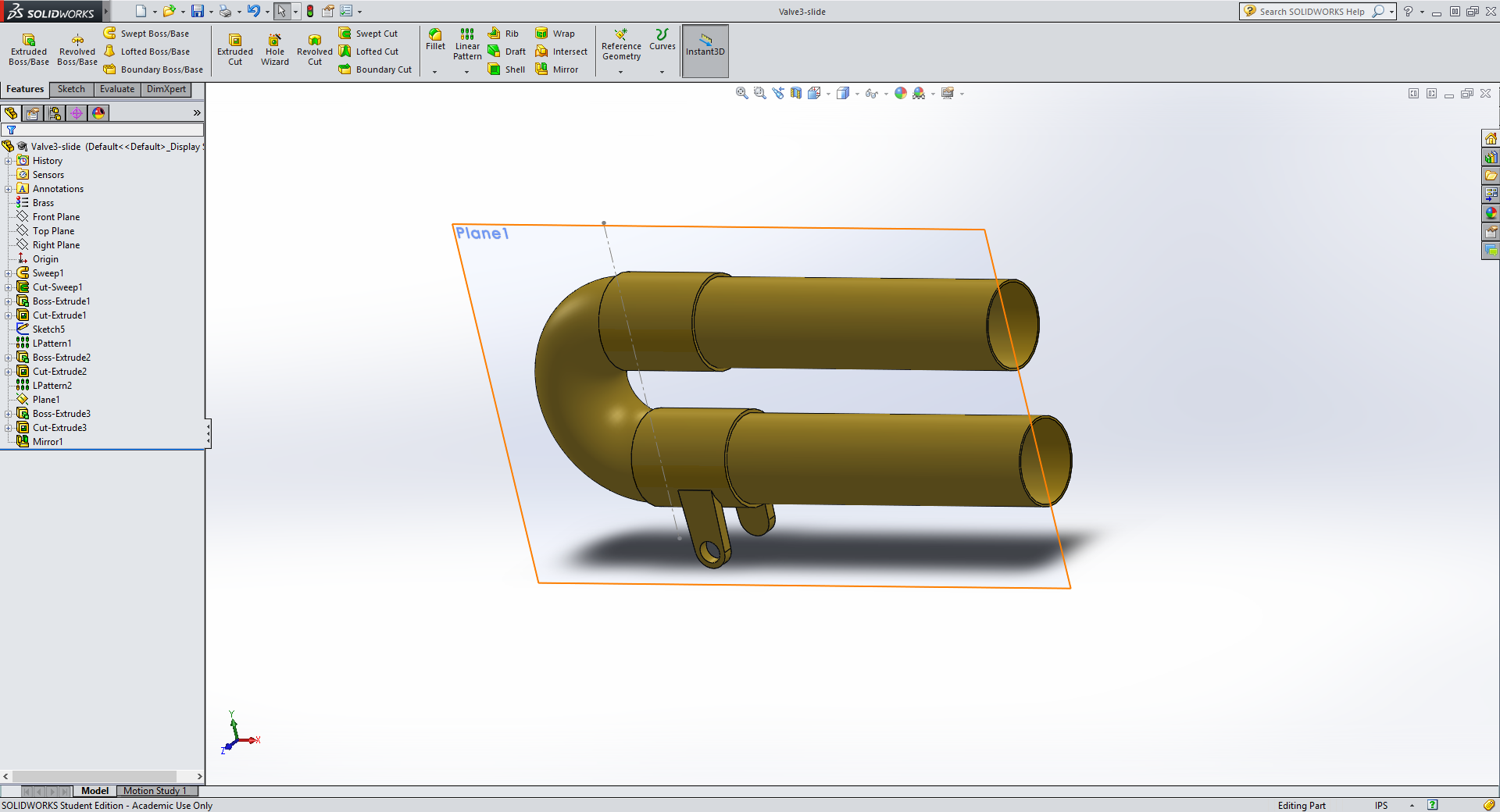

Iíve been modeling a cornet for my final project, !!!error: Indecipherable SUB-paragraph formatting!!!

Musicians of Oppo, can you name the part pictured above? (Almost finished)

dogisbadob

> TheHondaBro

dogisbadob

> TheHondaBro

03/11/2016 at 18:05 |

|

Iíll name it Larry.

aberson Bresident of the FullyAssed Committe

> TheHondaBro

aberson Bresident of the FullyAssed Committe

> TheHondaBro

03/11/2016 at 18:09 |

|

its thing you slide to do things

miadaman? yes please

> TheHondaBro

miadaman? yes please

> TheHondaBro

03/11/2016 at 18:25 |

|

I believe the proper engineering term for it is ďthat bendy tuby thing with an adapter plug coming out of the bottomĒ.

Gone

> TheHondaBro

Gone

> TheHondaBro

03/11/2016 at 18:34 |

|

Valve slide? I dunno, I was a drummer.

How did you manage so many operations for that one part? *mind blown* Or are there internal things happening? But then why arenít they separate pieces? And why is there only a hole on one tab, not both? And why isnt that a 5 piece assembly? Ahhhhh!

tromoly

> TheHondaBro

tromoly

> TheHondaBro

03/11/2016 at 18:37 |

|

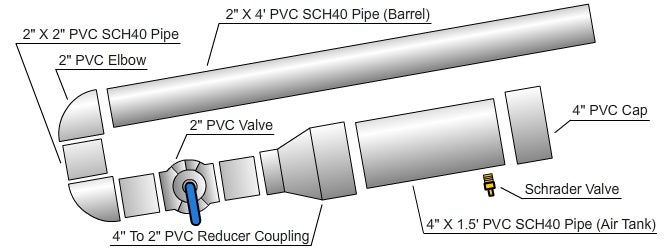

All I see is a form of potato cannon.

Die-Trying

> TheHondaBro

Die-Trying

> TheHondaBro

03/11/2016 at 19:17 |

|

p trap for a sink?

Frank Grimes

> TheHondaBro

Frank Grimes

> TheHondaBro

03/11/2016 at 19:46 |

|

jet butt?

BmanUltima's car still hasn't been fixed yet, he'll get on it tomorrow, honest.

> TheHondaBro

BmanUltima's car still hasn't been fixed yet, he'll get on it tomorrow, honest.

> TheHondaBro

03/11/2016 at 19:48 |

|

Thatíd be a tuning slide.

TheHondaBro

> BmanUltima's car still hasn't been fixed yet, he'll get on it tomorrow, honest.

TheHondaBro

> BmanUltima's car still hasn't been fixed yet, he'll get on it tomorrow, honest.

03/11/2016 at 20:02 |

|

YES.

Which valve though?

TheHondaBro

> dogisbadob

TheHondaBro

> dogisbadob

03/11/2016 at 20:02 |

|

k

TheHondaBro

> aberson Bresident of the FullyAssed Committe

TheHondaBro

> aberson Bresident of the FullyAssed Committe

03/11/2016 at 20:02 |

|

sure

TheHondaBro

> miadaman? yes please

TheHondaBro

> miadaman? yes please

03/11/2016 at 20:02 |

|

Pretty much.

TheHondaBro

> tromoly

TheHondaBro

> tromoly

03/11/2016 at 20:02 |

|

Not a potato cannon.

TheHondaBro

> Gone

TheHondaBro

> Gone

03/11/2016 at 20:03 |

|

Itís all one piece.

FTTOHG Has Moved to https://opposite-lock.com

> TheHondaBro

FTTOHG Has Moved to https://opposite-lock.com

> TheHondaBro

03/11/2016 at 20:03 |

|

3rd slide valve. It helps that you left the tree open so that we can see you named the part valve3-slide.sldprt ;)

TheHondaBro

> FTTOHG Has Moved to https://opposite-lock.com

TheHondaBro

> FTTOHG Has Moved to https://opposite-lock.com

03/11/2016 at 20:04 |

|

Damn, well yes.

TheHondaBro

> Die-Trying

TheHondaBro

> Die-Trying

03/11/2016 at 20:04 |

|

No.

BmanUltima's car still hasn't been fixed yet, he'll get on it tomorrow, honest.

> TheHondaBro

BmanUltima's car still hasn't been fixed yet, he'll get on it tomorrow, honest.

> TheHondaBro

03/11/2016 at 20:05 |

|

Valve number one, or the one closest to you.

(I played various brass instruments for 5 years in highschool)

TheHondaBro

> BmanUltima's car still hasn't been fixed yet, he'll get on it tomorrow, honest.

TheHondaBro

> BmanUltima's car still hasn't been fixed yet, he'll get on it tomorrow, honest.

03/11/2016 at 20:10 |

|

Wrong. 3.

FTTOHG Has Moved to https://opposite-lock.com

> Gone

FTTOHG Has Moved to https://opposite-lock.com

> Gone

03/11/2016 at 20:12 |

|

Putting the hole on one tab is actually pretty easy - you just click on the tab surface to make a sketch plane, sketch a circle on the tab, make an extruded cut and tell it ďup to nextĒ and SolidWorks just cuts to the next surface.

But yeah there is a lot going on here for a single part. Maybe class requirements to demonstrate a bunch of operations that were taught?

FTTOHG Has Moved to https://opposite-lock.com

> TheHondaBro

FTTOHG Has Moved to https://opposite-lock.com

> TheHondaBro

03/11/2016 at 20:15 |

|

Was the swept cut a class requirement? It seems like it would have been easier to just sketch a ring and do a swept extrusion of that. Or is there something internal to the part that I'm missing?

BmanUltima's car still hasn't been fixed yet, he'll get on it tomorrow, honest.

> TheHondaBro

BmanUltima's car still hasn't been fixed yet, he'll get on it tomorrow, honest.

> TheHondaBro

03/11/2016 at 20:15 |

|

crap. I was thinking about a trumpet.

Gone

> TheHondaBro

Gone

> TheHondaBro

03/11/2016 at 20:17 |

|

I know youíre a student, so I wasnít trying to be a dick btw. But given that list of steps it could be a lot simpler.

Good luck on the project. If you hit a roadblock, Iím sure Iím one of many SW users around here that can help.

FTTOHG Has Moved to https://opposite-lock.com

> TheHondaBro

FTTOHG Has Moved to https://opposite-lock.com

> TheHondaBro

03/11/2016 at 20:18 |

|

Show us the final assembly when itís done. Looking at the cornet in your other post it should be pretty damn impressive! Way more ambitious than anything I've done with SolidWorks.

TheHondaBro

> Gone

TheHondaBro

> Gone

03/11/2016 at 20:21 |

|

Probably.

Gone

> FTTOHG Has Moved to https://opposite-lock.com

Gone

> FTTOHG Has Moved to https://opposite-lock.com

03/11/2016 at 20:26 |

|

I would have thought the actual real world part would have been symmetrical. I was trying to figure out why his design wasnít. But good point about operations potentially being required/demonstrated in order to pass the class.

I have more combined hours in AutoCAD, IDEAS, UG/NX, ProE, SolidEdge, and SW than I care to count. ProE is the best and Iíll fight anyone that disagrees.

FTTOHG Has Moved to https://opposite-lock.com

> Gone

FTTOHG Has Moved to https://opposite-lock.com

> Gone

03/11/2016 at 20:41 |

|

Makes sense - misunderstood what you were asking sorry.

I learned solid modeling on Pro/E back in 2004. I remember hating it so much at the start but defending it in the end for all of the things I hated at the start. I lived in Europe in 2005 and had to learn CATIA and couldnít stand it compared to Pro/E.

We mostly use SW where I work now, so Iíve learned to live with it and itís basically all Iíve used for 8 years or so now. Didnít Pro/E become Creo a few years back? We have a couple Creo licenses around and they seem to use the same versioned file extensions as Pro/E did back in the day. All I ever do with it is open models from our customers and either make measurements or export the parts as IGES files to open in other software.

Gone

> FTTOHG Has Moved to https://opposite-lock.com

Gone

> FTTOHG Has Moved to https://opposite-lock.com

03/11/2016 at 20:54 |

|

No biggie, adter re-reading it, the comment didnít come across well at all via the internet.

I keep forgeting itís Creo now. We kept calling it ProE after the tranition. Impressive, thatís a lot of time on one platform. I hopped around and ended up getting seat time with everything but CATIA. Iíve heard mixed reviews with it.

gmporschenut also a fan of hondas

> TheHondaBro

gmporschenut also a fan of hondas

> TheHondaBro

03/12/2016 at 02:07 |

|

i miss SW.

TheHondaBro

> gmporschenut also a fan of hondas

TheHondaBro

> gmporschenut also a fan of hondas

03/12/2016 at 02:20 |

|

I started learning Solidworks after having been using Inventor. Itís like a breath of fresh air after having been left outside in a sandstorm.

Jdrentarol

> TheHondaBro

Jdrentarol

> TheHondaBro

03/12/2016 at 08:02 |

|

Itís a part of a trombone.

Jdrentarol

> tromoly

Jdrentarol

> tromoly

03/12/2016 at 08:03 |

|

Is that a Stef Schrader valve I see?

MM54

> TheHondaBro

MM54

> TheHondaBro

03/12/2016 at 11:40 |

|

Once you finish the model, you need to run some CFD through it... probably would be really interesting, actually.

ttyymmnn

> TheHondaBro

ttyymmnn

> TheHondaBro

03/12/2016 at 13:15 |

|

Yes......

ttyymmnn

> TheHondaBro

ttyymmnn

> TheHondaBro

03/12/2016 at 13:16 |

|

Well, in the hands of some people, maybe. Or a clam cannon.

TheHondaBro

> ttyymmnn

TheHondaBro

> ttyymmnn

03/12/2016 at 13:18 |

|

Spit cannon.

ttyymmnn

> TheHondaBro

ttyymmnn

> TheHondaBro

03/12/2016 at 13:20 |

|

Said to every parent of a trumpet student: ďItís not spit. Itís water . No, really!Ē